Combustion Chamber Design

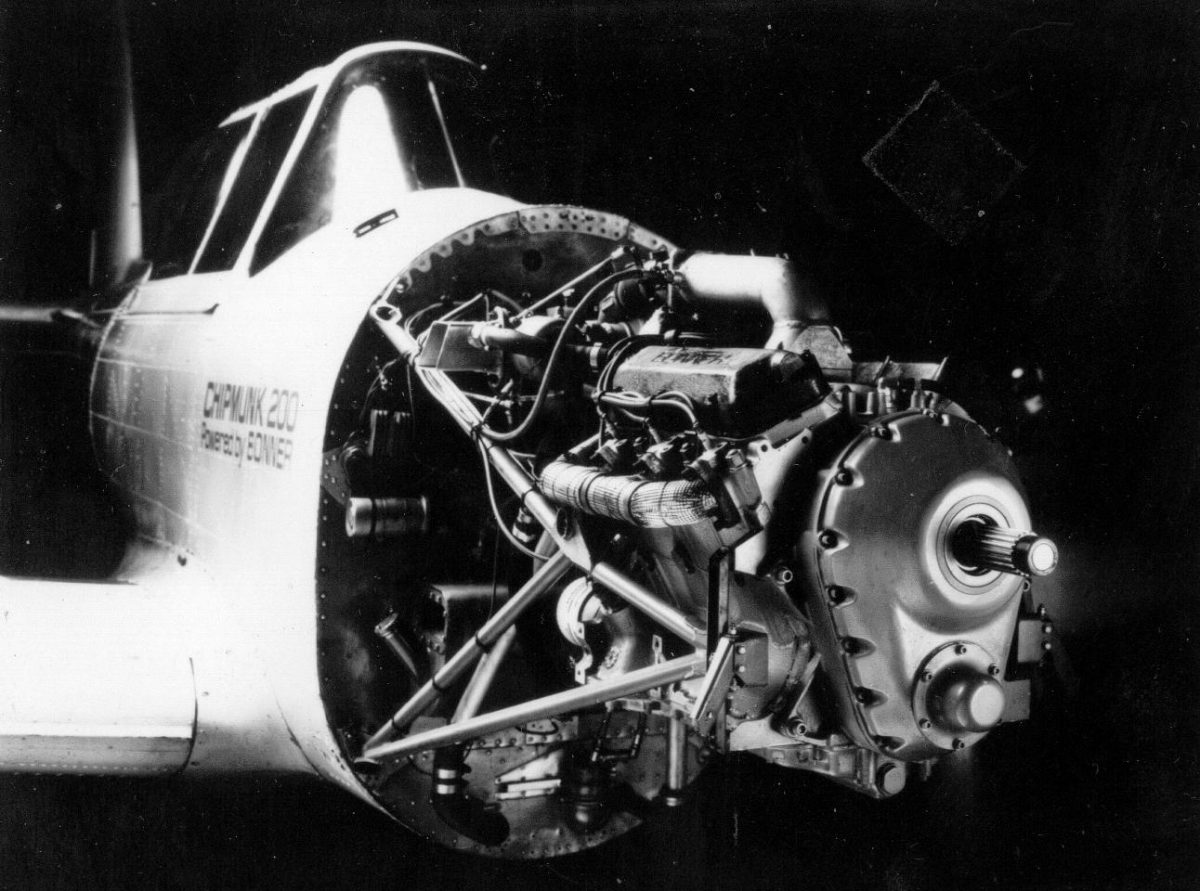

Our involvement in aero engines always centred around the Aero Bonner Super Sapphire 200 h.p. aero engine.

Designed by Bill Bonner in the early seventies, it took to the air installed in a Chipmunk Mk22A in July 1979, and was an astounding technical success.

Bill flew it at the 1980 Farnborough Airshow, when the RAF put in a request to re-equip their fleet of Chipmunks with the Sapphire engine, and Rolls-Royce announced their desire to take over and manufacture the engine in quantity.

Uh Oh. At the Farnborough exhibitors dinner, guest of honour, Margaret Thatcher, said her government. was happy to be a first customer for the kit on show, but we should also look to make our profits from the wider world. Fair enough; so Bill wrote to the PM, saying that the RAF wished to purchase the Bonner V6 aero engine for their Chipmunks, and could the MOD kindly put in a purchase order. Unfortunately, there was a moritoreum on defence spending, came the reply from No 10, ( plus ca change ), and the govt. could not afford it. ( So much for the rhetoric ). Furthermore, by the end of 1980, R-R told Bill that they thought that the Bonner engine was pointing the way to the future of light piston aero engines, but nevertheless they were going through a divorce from Continental Motors and pulling out of light aviation altogether, and reluctantly could not remain in the sector for this engine alone.

While all this was going on, we were fairly high profile at Shoreham, and lots of people would ask us to overhaul, or rebuild, or tune their Lycoming/Rolls-Royce/Continental/De Havilland engines, and we were more than happy to oblige. Also we were certifying the Sapphire engine and the installation in the Chipmunk through the CAA, and had a very good raport with the higher etchelons, which was very helpful in other areas. For example, it enabled us to obtain approval to modify the Bronze Gipsy Major heads with a steel S111 valve seat, with a minimum of fuss. We modified about 50 engine sets in all.

We also obtained approval to substantially raise the power of the Lycoming IO-360 engine, which was popular with British Aerobatic Team.

We prepared several R-R 0-200 engines for racing. A few successful Formula 1 aircraft, and one Kings Cup victory. Bill Bonner also won the Kings Cup in 1973.

With this background, we have been zero time overhauling all types since 1976. Bill Bonner holds a CAA D licence covering all types worldwide. The largest we have overhauled so far is a 425 h.p. Lycoming TIGO-541-E, out of a pressurised Navajo, and the smallest several R-R 0-200 engines, including everything in between.

All the engines we overhaul are dynamometer tested before release. This one of the most important features of the entire process. We initially run the engine under a light load and moderate speed to settle the bearings, cam, tappets etc, and then gradually increase load and speed to apply gas pressure to the rings to bed them in. Finally we almost invariably run the engine at full power for 60 minutes without a break. It feels longer than an hour! If the engine is still giving full power at the end of that, it is in perfect condition, and that is the idea.